DT Swiss is on a mission, a mission to bring eMTB riders the components they need. The people behind this mission are people who know, understand and most importantly, RIDE eMTBs. So go ahead and discover our understanding of what eMTBs are here for and discover the technologies we apply to make it happen.

Ride

FURTHER

250 watts of extra power broaden the horizon even for the fittest of us: Energy sapping ground and snowy rides just get a whole lot more fun. And what used to be an epic ride turns into a two hour experience condensing the vertical gained, the trails ridden and the vertical crushed. It’s really like riding TO HEAVEN AND BACK.

Ride

HARDER

Going on your familiar rides with the power of an olympic XC athlete lets you start to see the terrain with different eyes: Reverse the direction and you notice riding up trails is a lot of fun. Riding a root carpet at twice the speed, that long, painful push up the baby head gravel road to get to ride that secret trail? Now a game of navigating the obstacles, it allows you to TURN PAIN INTO FUN.

SHARE

THE RIDE

Beyond bringing new people into the wonderful sport that mountainbiking is, eMTBs allow die hard athletes to share their riding adventures with their partners, their kids and virtually anyone who ever dreamed to go fast and far. Seasoned mountainbikers starting to feel their age continue to do their demanding loops. And riders who have to wear many hats in real life can still join their wednesday night group ride. So yes, eMTBs really are making sure that EVERYONE ROCKS AND ROLLS.

WHAT

MEANS

TO US

To us an eMTB simply is a machine for a different mountainbiking experience. Even though the power comes from both the machine and the rider, the fun is all for the latter. We set out on MISSION HYBRID with this mindset, to develop components for eMTBs which are just as specialized as components for purely muscle powered bikes are.

WHAT THAT

MEANS FOR

COMPONENTS

An eMTB is much like a german sportscar: You expect it to work flawless all the time: When you hop in for a sporty summer drive where you slam through the gears AND when you commmute in it during winter, just happy that the heating works. Fact is, you want it to perform AND be reliable. This is just what our HYBRID wheels deliver. Follow us on the next pages to find out just how they do it.

PERFOR

MANCE

AND RELIABILITY

ARE KEY

THE AVERAGE eMTB RIDERS SEASON

-

3500 KM

Average distance

covered. -

180 NM

Peak system

torque. -

70'000 M

Elevation gained

(& destroyed) -

400 W

Average power

output. -

21 KM/H

Average speed.

WHAT IS THE DIFFERENCE?

EVERYTHING.

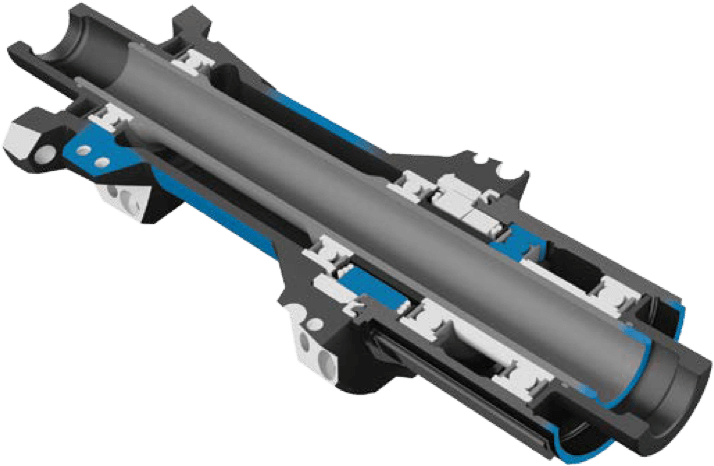

HYBRID HUBS

INNER BEAUTY

HYBRID hubs feature increased wall thickness in the oversized shell, high load axles and oversized spoke interfaces. This is complimented by new hardened steel 24T ratchets, oversize bearings and steel rotors. Via this clever optimization we have achieved a 150 kg system weight classification with only a minimal weight increase compared to same level MTB hub. The result is a gem of a hub that can withstand huge torque loads, offers quick engagement and when used in combination with our HYBRID system components is part of an amazingly robust wheel set.

Engineered as a complete system with high torque loads in mind, the HYBRID system easily converts pedal and engine input into forward motion

Steel rotorsIn order to withstand the high torque loads put out by modern e-drive systems, we have made the new HYBRID freehub bodies out of steel. Available for both Shimano and Sram XD they provide a more durable interface for your cassette.

Oversize BearingsAll bearings in the hub are oversized to endure higher loads and to allow smooth running under extreme conditions. In this case, bigger is better.

HYBRID specific 24T RatchetsHYBRID system specific: 24T hardened steel ratchets provide the ultimate in durability while providing quick engagement for a snappy ride feel.

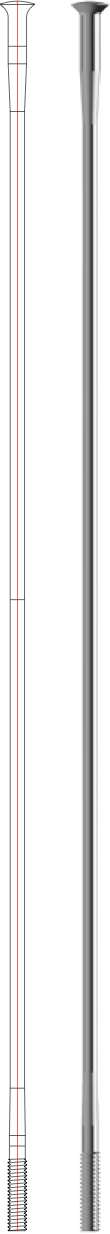

HYBRID SPOKES

NEW SPOKES FOR A NEW WAY OF RIDING

To complete our HYBRID system, we required spokes that are able to not only withstand the increased weight and torque of a modern eMTB, but must also pair perfectly with the oversized dimensions of the HYBRID hubs. Specially designed straight pull spokes feature reinforced and oversized straight pull heads that together with DT Pro Lock® Squorx nipples help transfer all the power you put into the hub into forward motion. Overlooked by many, re-engineered by DT Swiss for the next generation of e-bikes, HYBRID spokes can walk the walk.

HYBRID RIMS

More material for more e-power.

Putting in a lot of vertical on an eMTB in rough terrain means a hard life for rims. DT Swiss HYBRID rims feature our signature profile designs and optimized cross sections and are approved to a higher system weight of 150 kg. We have added strength and material where it makes sense in order to deliver tough, e-bike specific rims that are offered in a range of widths to match any type of riding on any type of terrain. Like those robots said: Harder, better, faster, stronger.

ENDURO RIMSUsing tried and true alloys and World Cup winning construction, our Enduro rims' proven profiles are the big mountain standard.

HYBRID RIMSDT Swiss HYBRID rims are engineered with increased wall thickness and classified for a 150 kg system weight. Available in 25, 30 and 35 mm widths for increased traction and comfort.

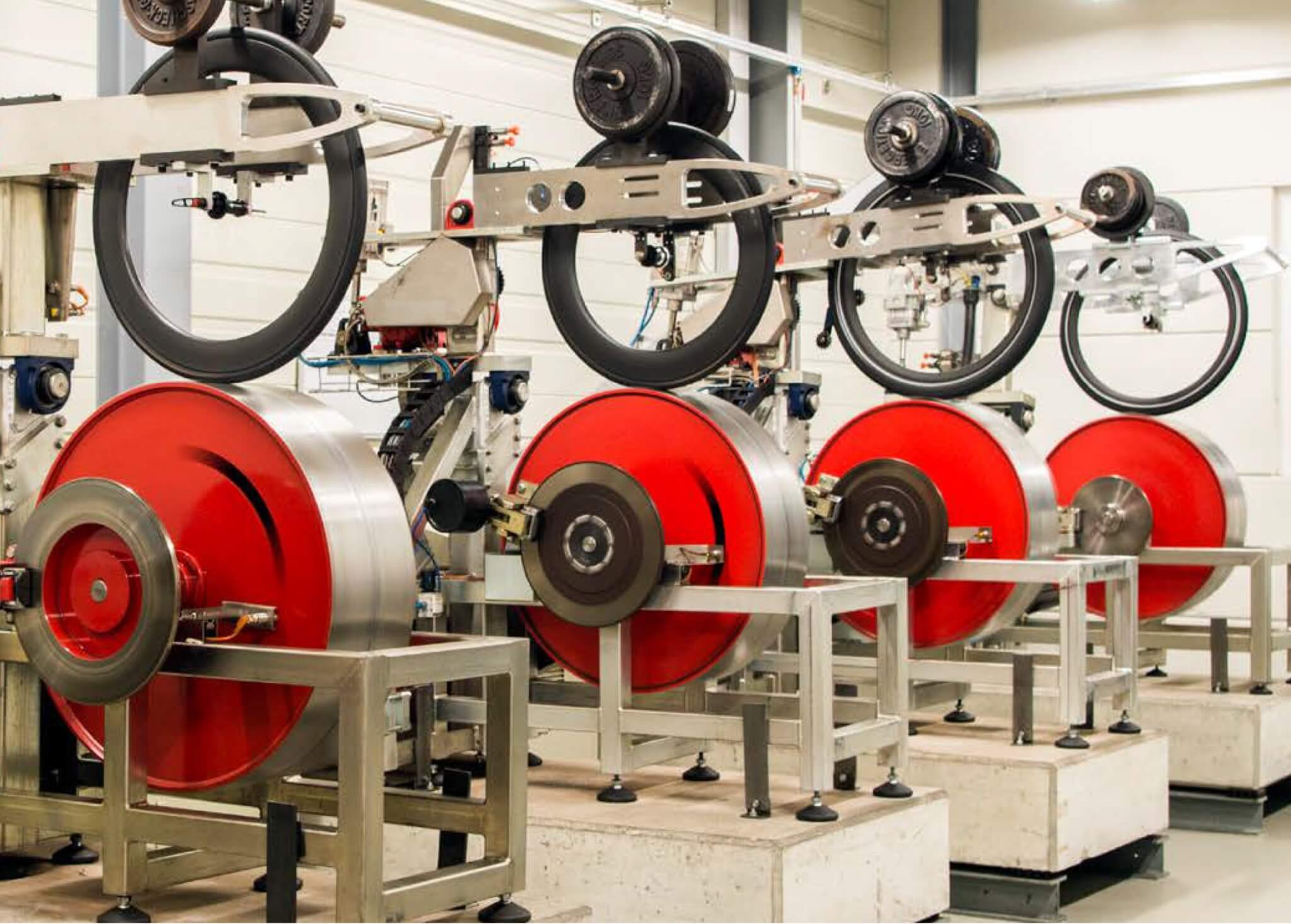

THE LAB

The lab is where our HYBRID components are put to the test. Here we keep refining and finding new test procedures to simulate what happens on the trail as accurately as possible. All with one goal:To make your wheels even better and develop them even faster than today.

Over the twenty years DT Swiss has been developping wheels, we have gathered an unparalleled testing know-how.

With this know-how and a tightly knit test rider group, we are able to design a wheel just right for its intended

use. By veryfing and knowing the loads occurring in real world riding, our in-house wheel testing equipment can

quickly go through a wheels whole lifetime to double check its performance for the intended use. Still many

iterations are needed to find that perfect strength to weight ratio for a given application. To do these product

development iterations, you need the ability to quickly prototype products. We have set up a global network of

inhouse and external specialists who make this happen.

It’s the network Philipp Lüdi, Manager Prototyping, has built and is leading. Being a die hard mountain biker

himself, he also makes sure that the wheel prototypes that are tortured on the test benches, also hit the dirt

as quickly as possible. Because in the end, what a rider feels through his arms, legs and butt is what ultimately

counts.

TESTING & TECH

The results of our HYBRID test standards can be boiled down to two essential points: 1. Certain areas of each component must be strengthened. 2. There are areas of each component that can be kept just as lightweight as their MTB counterparts. With these two points in mind we were able to tease every bit of strength out of a quite lightweight package. Read on below to find out what we tested and how our design engineers use the results to shape our products.

HUB

HYBRID hub extraordinaire

Modern eMTB's pose a whole new set of challenges for ordinary bike components, more km's, more vertical, more weight and more torque. Our HYBRID hubs not only withstand torque load tests of up to 500 NM, but they also feature a 150 kg system weight classification which acknowledges each of their robust and oversized features. Nothing has been left untouched, and these hubs are designed to go the distance.

HYBRID specific ratchets

18 / 36T

18 / 36T

24T

24T

Torque test

400 Nm

Standard MTB hub

HYBRID hub

500 Nm

Maximum bearing load

Tested to min.

2080 N

Standard MTB hub

HYBRID hub

4100 N

SPOKE

Standard MTB Spoke vs.

HYBRID spoke.

HYBRID specific double butted spokes are certified to 150 kg and tensile strength tested to exceed our normal MTB standards by up to 35%.

Spoke head tensile strength

100% Reference

Standard MTB spoke

HYBRID spoke

135% Above reference

Minimal weight gain

225 grams 32 pcs 280 mm

Standard MTB spoke

HYBRID spoke

230 grams 32 pcs 280 mm

Durability test

Tested to min.

185 Standard lifecycles @ 120 kg

Standard MTB spoke

HYBRID spoke

280 Standard lifecycles @ 150 kg

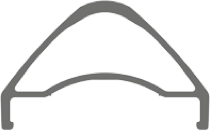

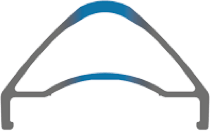

RIM

Enduro rim vs. HYBRID rim

Every rim in the HYBRID collection is subjected to torturous test loads that are calculated to replicate the added torque and stress generated by modern eMTB's. Our HYBRID rims are engineered with robust profiles and compared to our Enduro rims feature an increased wall thickness in order to withstand higher spoke pull out forces. All rims must pass extended endurance tests of up to 27 standard lifecycles at a 150 kg system weight in order to receive our new HYBRID label.

Spoke pull out force

100% Reference

Standard MTB rim

HYBRID rim

20% Above reference

Loaded dynamic test

120 kg system weight

Standard MTB rim

HYBRID rim

150 kg system weight

Durability test

Tested to min.

13 Standard lifecycles

Standard MTB rim

HYBRID rim

27 Standard lifecycles

THE LIFE

Our HYBRID components are developed with all the passion we have for our sport. A passion powered by lunchrides, epic weekends in the alps and a tight knit team at work. We truly live performance eMTBs. While every single employee at DT Swiss has embraced the new perspectives eMTBs bring to our sport, there are two main characters responsible for the HYBRID components to be what they are: Strong, reliable and high performance. Exactly what’s needed on todays super capable bikes and exactly what demanding riders are looking for. Find out about who those two individuals are.

NICK BALLAHYBRID PRODUCT MANAGER DT SWISS

MOUNTAIN BIKER SINCE 1986

WE LIVE

PERFORMANCE

eMTB

At DT Swiss, Ideas for concepts such as the HYBRID line up start in the Product Managament and Design department. Everyone felt the rise of the eMTB needed a response as far components go, but it was Daniel Berger and Nick Balla to define where electrically assisted Mountainbiking is heading and what type of wheels that use would demand. Being deeply involved in the industry for a long time and passionate riders for longer than they can remember, Daniel and Nick where just the ticket to nail this task.

The eMTB has lit my fire for the sport like the first Stumpjumper I bought back in 1986 has, when I first put its

knobbies to the dirt.

I immediately knew that these bikes will have a great future and slowly realized what we could contribute to make

them even greater. Once we had mission HYBRID outlined, we quickly worked together as an organization to make

it happen.

I am super stoked on how it came out and I am even more stoked for what’s coming up.

DANIEL BERGERVICE PRESIDENT MARKETING DTSWISS

MOUNTAIN BIKER SINCE 1986